The web de-dusting module PEM removes the dust from the paper webs. The PEM has two de-dusting heads for cleaning both sides of the paper web in continuous operation.

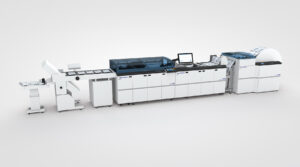

Roll to fold solution with Web Merger WM8

Roll to fold with WM8

The paper web provided by the Unwinder UW8 is pulled in by the Web Merger WM8 and cut longitudinally. The edges can be trimmed simultaneously. After that, the two web halves are placed on top of one another in the Web Merger and fed to the Cross Cutter. During the merging process, the right web half can be placed below or above the left web half. Optionally, the web can pass through the Web Merger without being merged.

| Max. roll diameter | 54" (1370 mm) |

| Web width | 16" – 22.5" (406 – 571 mm) |

| Production speed | up to 600 ft/min (180 m/min) |

| Paper weight | 40 – 300 g/m2 Merge: 60 – 130 g/m2 |

| Longitudinal gutter cut width | 6, 8, 10 or 12 mm |

| Variable chip out | 1/4" – 1" (6.35 – 25 mm) |

| Final format length | 5.5" – 62" (140 – 1575 mm) |

| Edge trimming width | 8 – 25 mm |

Workflow

Merge process

Options

Dynamic vertical and cross perforator DP8

The dynamic perforating module DP8 can be used to create variable longitudinal and cross perforations.

Pile stacker PST-52

The pile stacker PST-52 is equipped with two easily removable standard paper trolleys. Once the stack is full, users simply roll out the full trolley, roll the second empty trolley into the stacker and continue production. Additional trolleys are available as an option.

Web Inspection System

A Web inspection system checks the quality and content of the printed pages. With the WI8 Web Inspection system you can check quality and content of the printing on each page in terms of colors, positions, contours, smearing, jetouts, data validation, etc. It is always possible to update it with new functions and extend it to a complete tracking solution.

Full Bleed products

The combination of longitudinal and cross cut-out (module CS8) allows the user to produce full-bleed products.

Hello!

We LOVE and LIVE paper.

We also LOVE staying in touch with people so just give us a call or drop us a line. We look forward to hearing from you.

Hunkeler AG Paper Processing

Bahnhofstrasse 31

CH -4806 Wikon

Schweiz

Phone: +41 62 745 61 61

E-Mail: info@hunkeler.ch