A Web inspection system checks the quality and content of the printed pages. With the WI8 Web Inspection system you can check quality and content of the printing on each page in terms of colors, positions, contours, smearing, jetouts, data validation, etc. It is always possible to update it with new functions and extend it to a complete tracking solution.

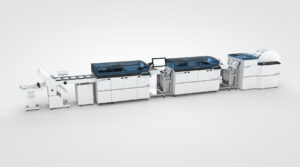

Direct-Mail solution with DP8 and buckle folder

Direct-Mail production

Producing first-class, four-color printed mailings even on coated paper from the roll to the cut and folded end-product. Dynamic punching, vertical and cross perforation is performed in the DP8-II-P punching and perforation module. The double cross-cutting cylinder in the Cutter CS8 produces full-bleed documents. The cross-cutting cylinder in the CS8 can be equipped either with two knives for variable chip-out, or with one cutting knife and one perforating blade to produce dynamic folding perforations. The integrated WI8 Web Inspection System based on the latest highspeed CIS technology for high-end quality and integrity control.

| Max. roll diameter | 54" (1370 mm) |

| Web width | 8" – 20.5" (203 – 520 mm) |

| Production speed | up to 600 ft/min (180 m/min) |

| Paper weight | 40 – 300 g/m2 Perforating: 40 – 200 g/m2 Punching: 60 – 120 g/m2 Scoring: 120 – 250 g/m2 |

| Variable chip out | 1/4" – 2" (6.3 – 50 mm) |

| Final format length | 5.5" – 62" (140 – 1575 mm) |

Configurations

Dynamic perforation module DP8

Options

Control & Tracking Solution

The tracking system monitors ongoing prodcution in terms of completeness and accuracy.

Pile stacker PST-52

The pile stacker PST-52 is equipped with two easily removable standard paper trolleys. Once the stack is full, users simply roll out the full trolley, roll the second empty trolley into the stacker and continue production. Additional trolleys are available as an option.

Hello!

We LOVE and LIVE paper.

We also LOVE staying in touch with people so just give us a call or drop us a line. We look forward to hearing from you.

Hunkeler AG Paper Processing

Bahnhofstrasse 31

CH -4806 Wikon

Schweiz

Phone: +41 62 745 61 61

E-Mail: info@hunkeler.ch