The combination of longitudinal and cross cut-out (module CS8) allows the user to produce full-bleed products.

Booklet production with Müller Martini

Production of booklets

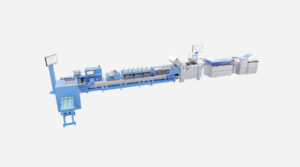

Magazines of varying page count are produced on a Müller Martini Prinova Digital saddle stitcher. The Unwinder UW8 will roll-feed the printed web into a high-performance Cross Cutter CS8. The DynaCut function will allow signatures with varying page counts to be produced. The signatures are then folded in a buckle fold machine and saddle stitched on the saddle stitcher at a web speed of up to 200 meters per minute or up to 9,000 cycles/h.

| Max. roll diameter | 54" (1370 mm) |

| Web width | up to 22.5" (571 mm) |

| Production speed | up to 650 ft/min (200 m/min) |

| Paper weight | 40 – 300 g/m2 |

Options

Pile stacker PST-52

The pile stacker PST-52 is equipped with two easily removable standard paper trolleys. Once the stack is full, users simply roll out the full trolley, roll the second empty trolley into the stacker and continue production. Additional trolleys are available as an option.

Hello!

We LOVE and LIVE paper.

We also LOVE staying in touch with people so just give us a call or drop us a line. We look forward to hearing from you.

Hunkeler AG Paper Processing

Bahnhofstrasse 31

CH -4806 Wikon

Schweiz

Phone: +41 62 745 61 61

E-Mail: info@hunkeler.ch